Easy to Operate Stacker High-Level Stacker and Bag Stacker for Factory Production of Fertilizers

Manor Engineering has been maintaining close professional, technological, and international trade relations since 1987. Hena Tong Heavy Industry Science and Technology Co., Ltd. is a well-known and large enterprise specializing in the research, development, design, manufacturing, and sales of organic and compound fertilizer equipment. Founded in 1983, the company registered the “Tongda” brand in 2003. In 2004, it expanded to the Xingyang Longgang Development Zone, establishing a standardized heavy industrial facility covering 60,000 square meters. At the same time, it introduced internationally advanced large and medium-sized processing equipment, including 10 processing centers, 3 laser cutting machines, and more than 100 various production machines in total.

- Shipping:

Learn More

Basic Info.

Packaging & Delivery

Product Description

Product introduction

Product introduction

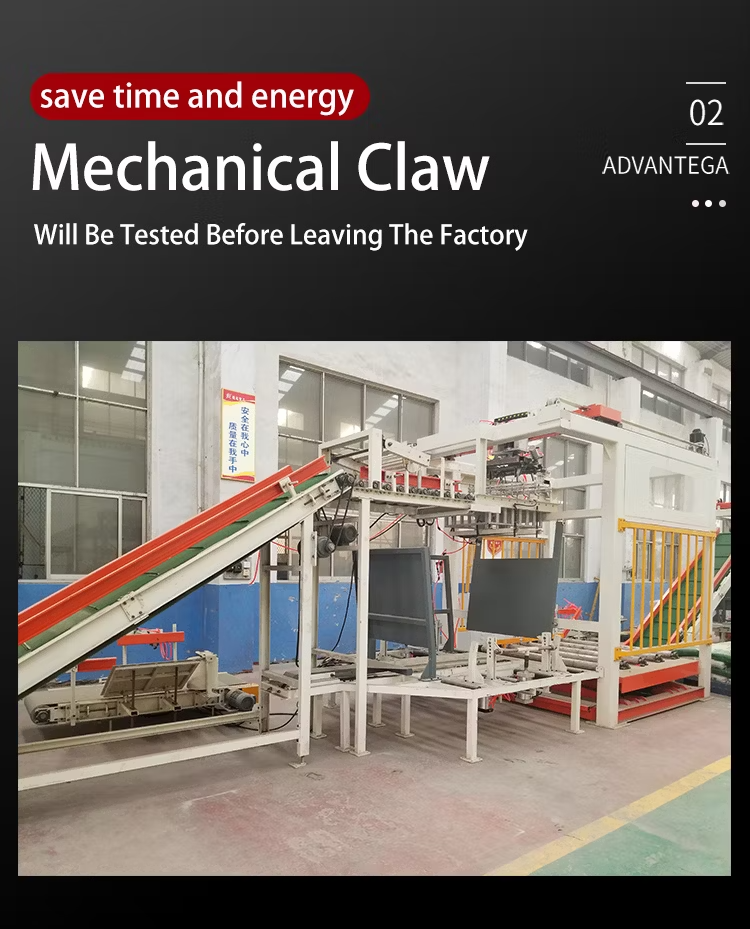

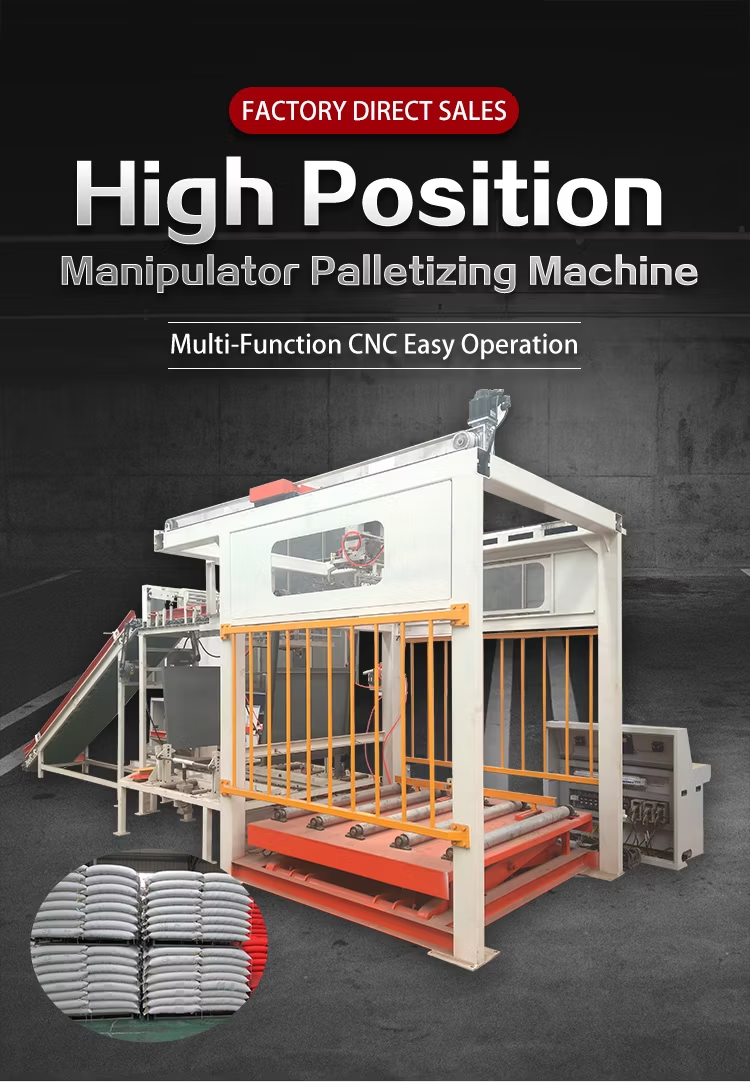

The organic fertilizer automatic palletizer is to put the bagged organic fertilizer on the tray and pallet (wood, plastic) according to a certain arrangement code, and carry out automatic stacking, stacking multiple layers, and then pushing out, so that the forklift can be transported to the warehouse. Stored equipment.

Performance characteristics

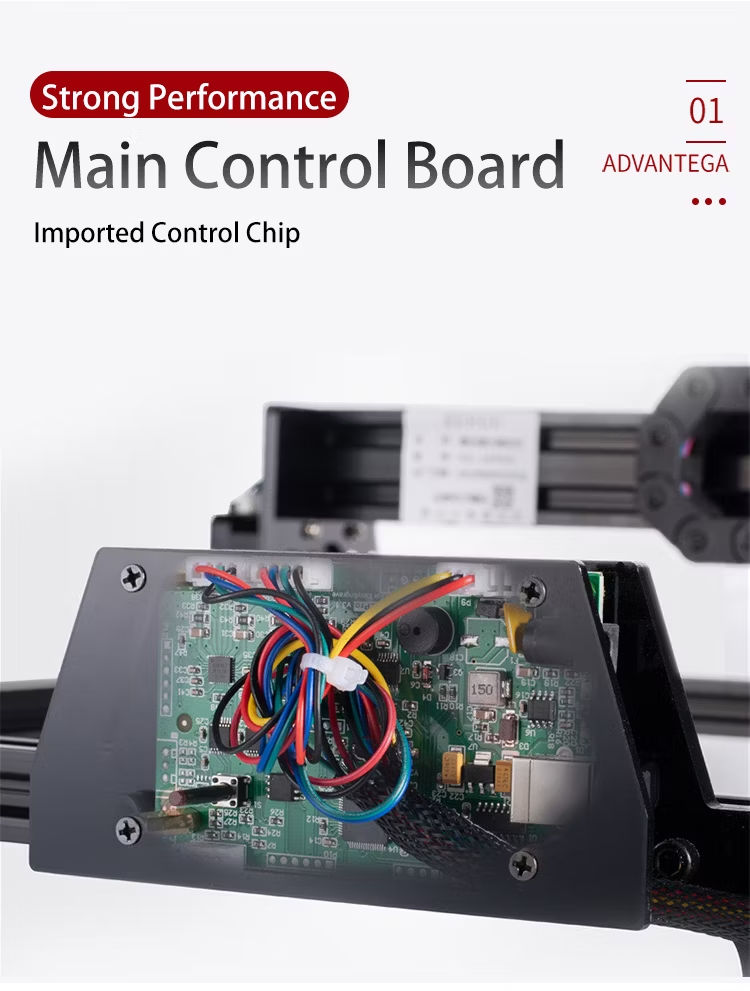

1.The equipment adopts the professional servo control system to simplify the mainpulator.The control system is full Chinese menu,Chinese prompt,intuitive learning,everyone can use.

2.The equipment can meet various needs of customers and set up different palletizing modes (the number of stacking layers and the number of pallets per layer can be easily controlled)

3.Most of the components of the equipment are national standard parts,simple maintenance,general accessories,to avoid the high cost of after-sales service and equipment maintenance.The core components are the world's top brand.

Working principle

The working principle of the organic fertilizer automatic palletizer is that a workpiece on the flat plate conforms to the requirements of the pallet, and the flat plate and the workpiece move forward until the vertical surface of the pallet. The upper bar is lowered, and the other three positioning bar starts to clamp, and the plate is reset. Each workpiece is lowered to the plane of the pallet, and the plane of the pallet is 10 mm away from the bottom surface of the panel, and the pallet is lowered by one workpiece height. Reciprocate the above until the pallet stacking code meets the set requirements.

Model | TDMD-500 |

Palletizing Speed | 500 |

Mainframe Size (mm) | 3200*2200*3000 |

Power (kw) | 7 |

Voltage(v) | 380 |

Palletizing Height (mm) | 600-1600 |

Stacking Layer Number | 1-10 |

Palletizing Station (bag) | 4-8 |

Gas Supply Pressure (Mpa) | 0.6-0.8 |

Weight (kg) | 2000 |