Small Blown Film Extruder for Plastic Masterbatch Testing

At Manor Engineering, we take advanced technologies — mainly from China, Europe, and the U.S. — and transform them into reliable, customized solutions for the Israeli market. Hardware arrives directly at our California R&D facility, where we redesign and prototype each product for optimal performance. From there, we move to scaled manufacturing, ensuring quality and consistency. By combining hardware, software, and multidisciplinary engineering, we deliver complete solutions — fully controlled by us and supported locally. No dependency on foreign service. No compromise on reliability.

$5500

- Shipping:

Learn More

Basic Info.

Model NO.

XH-430B

Type

PE Film Blowing Machine

Raw Material

PE

Maximum Folding Width of Film

300mm

Screw Diameter

25mm

Automation

Automatic

Computerized

Computerized

Machine Weight

600kg

Certification

CE, ISO9001:2008

Screw L/D

33:1

Screw Rotating Speed

0-95 Rpm

Main Motor Power

2.2kw

Film Thickness

0.02-0.2mm

Max Film Width

180mm

Transport Package

Wooden Box

Trademark

Xihua

Origin

China

HS Code

8477301000

Production Capacity

5-10kg/H

Packaging & Delivery

Package Size

215.00cm * 100.00cm * 230.00cm

Package Gross Weight

560.000kg

Product Description

Product Application

1) Application: PE, modified PP, modified PET, and other plastic materials which could be blown.

2) New material formula development.

3) Film blowing property test.

4) Master batch color dispersion test.

5) Optimization of blown film production technology.

6) Production of simple layer tubular film blowing.

Main Features

1) Specially manufactured screw and barrel to guarantee precision and quality;

2) International brand variable speed control motor to precisely control the screw rotating speed;

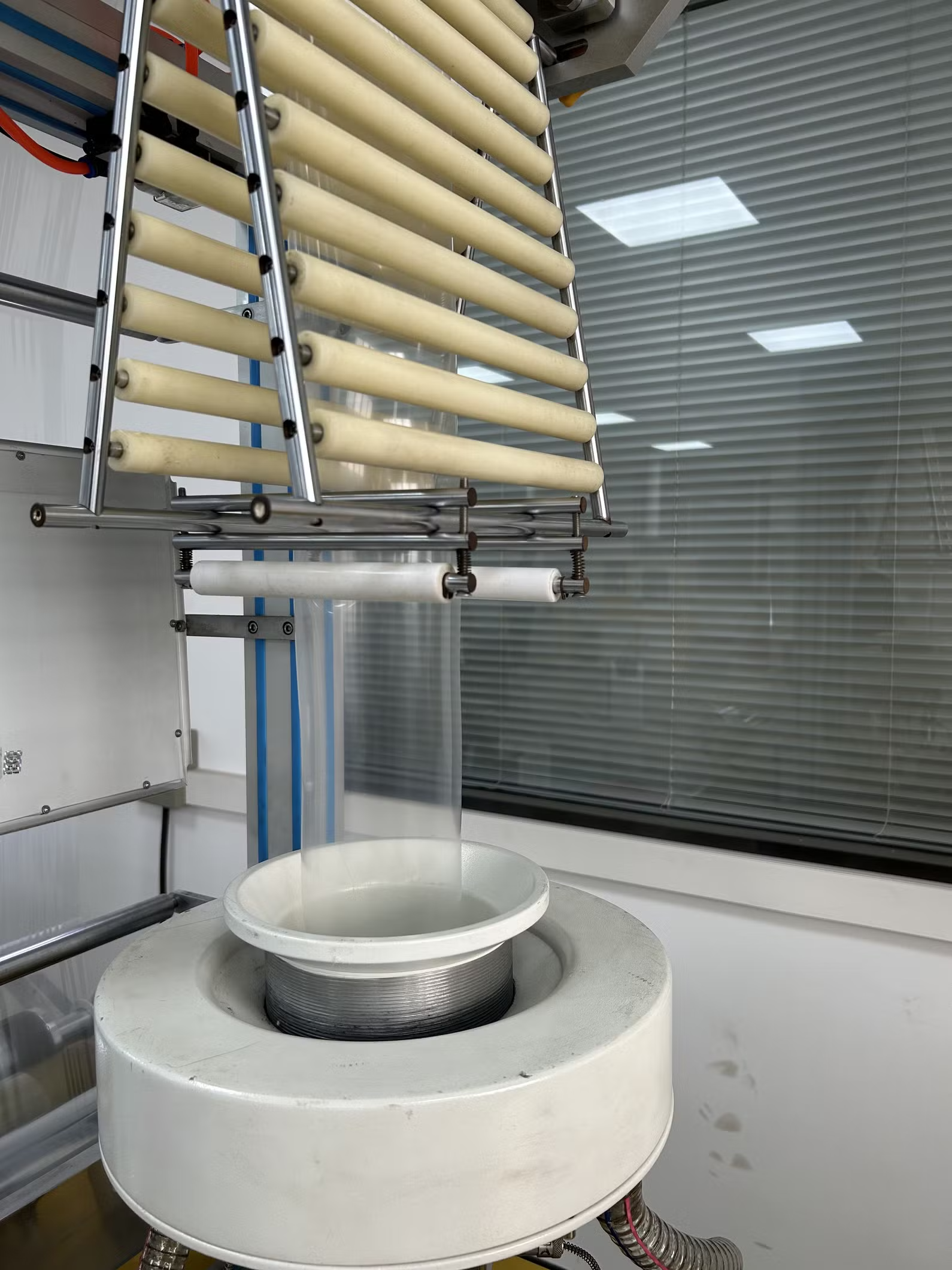

3) The lab blown film machine frame can be electrically lifted, which is easy to lead the film and adjust the production technology;

4) Equipped with retractable unit for the blown film frame to easily transport and move;

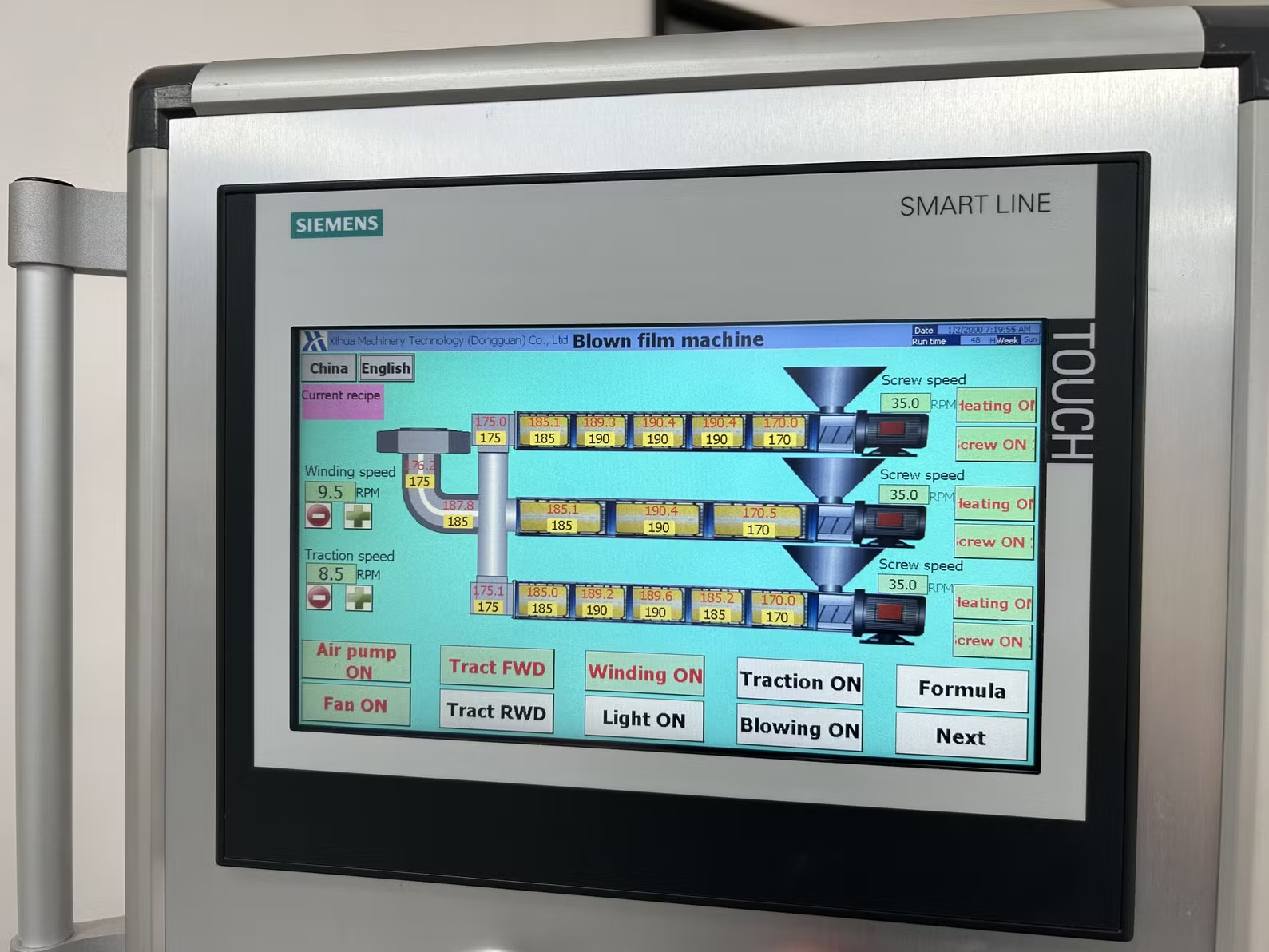

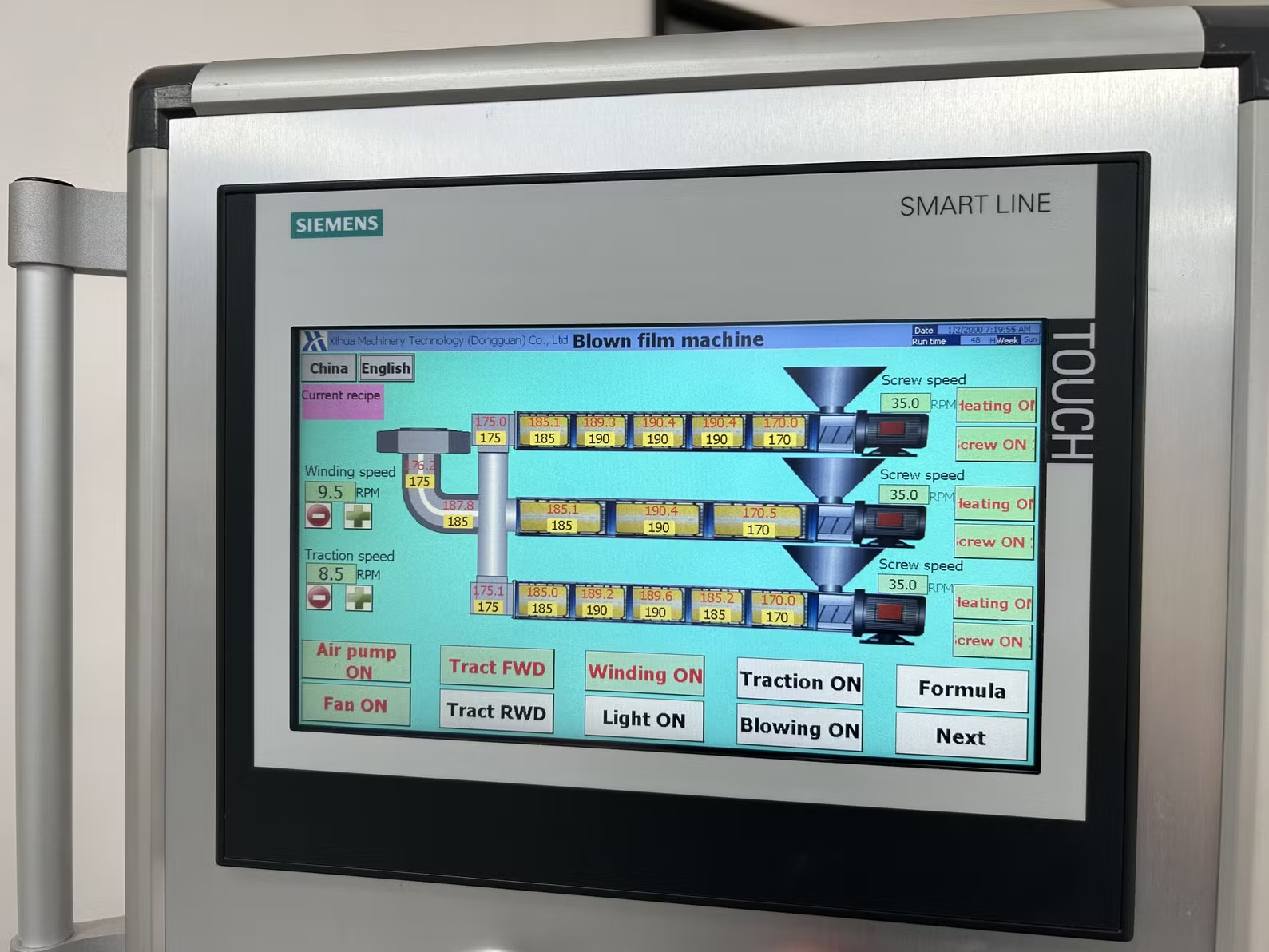

5) SIEMENS touching screen PLC control system.

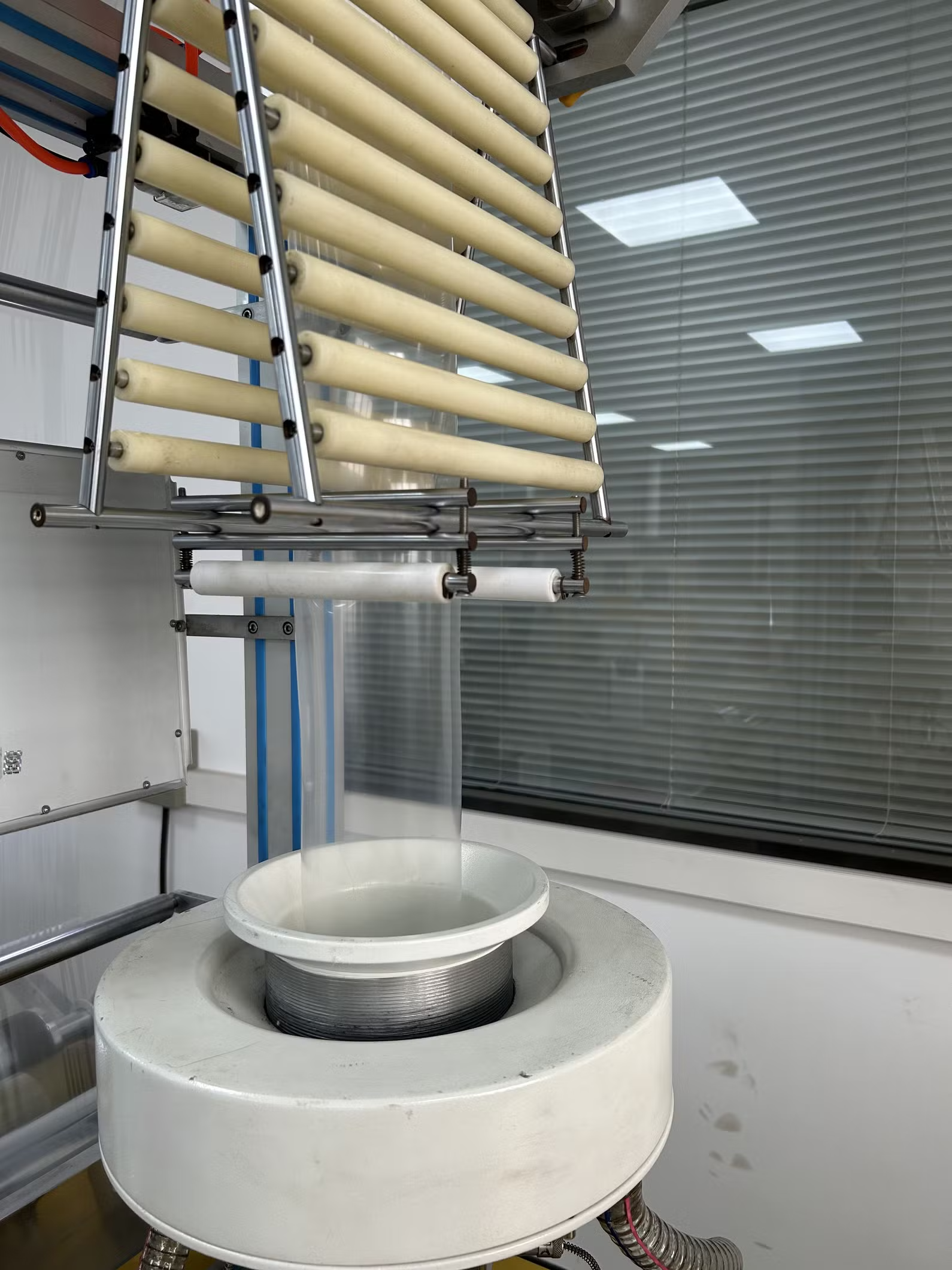

Details Images

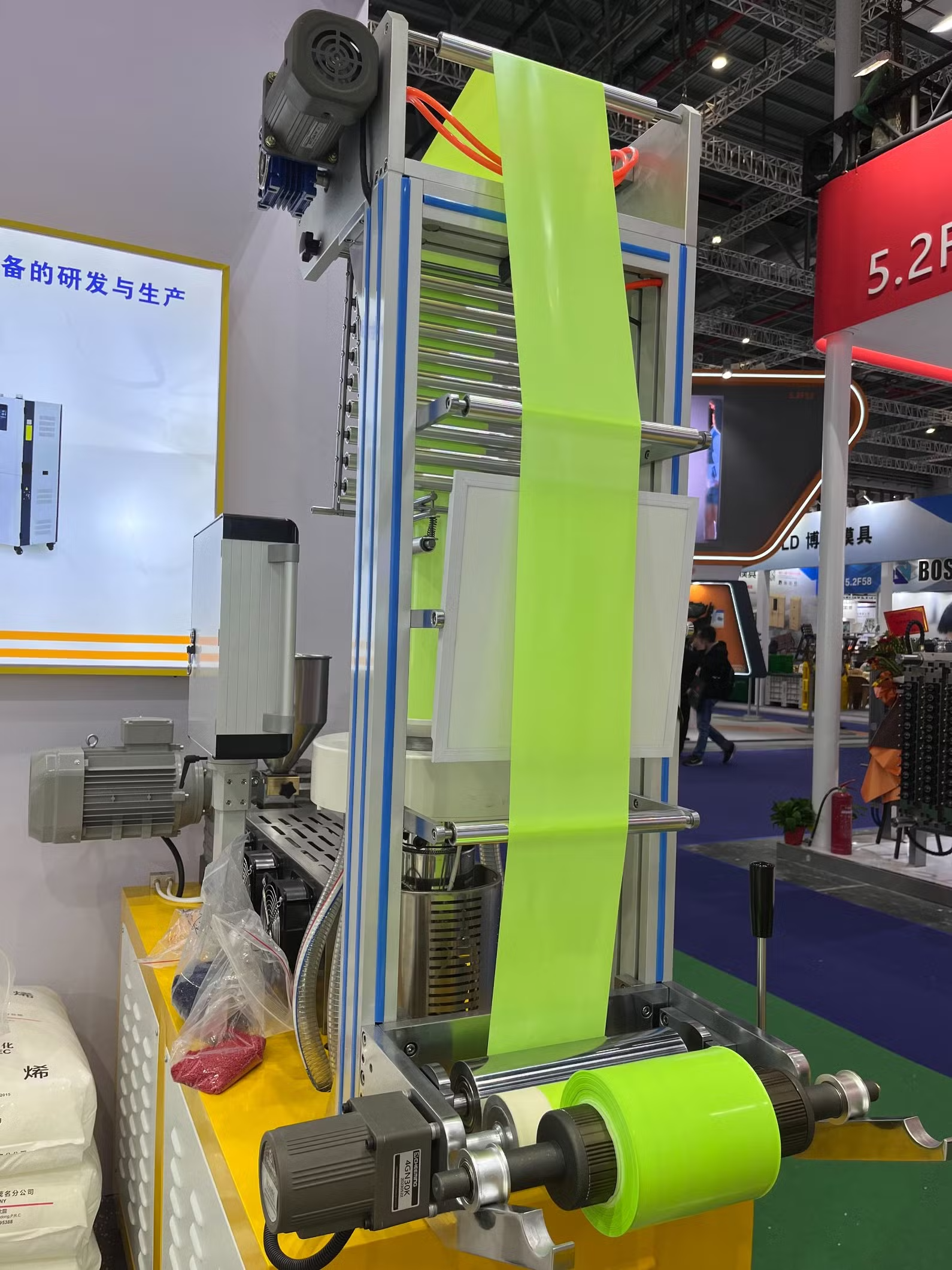

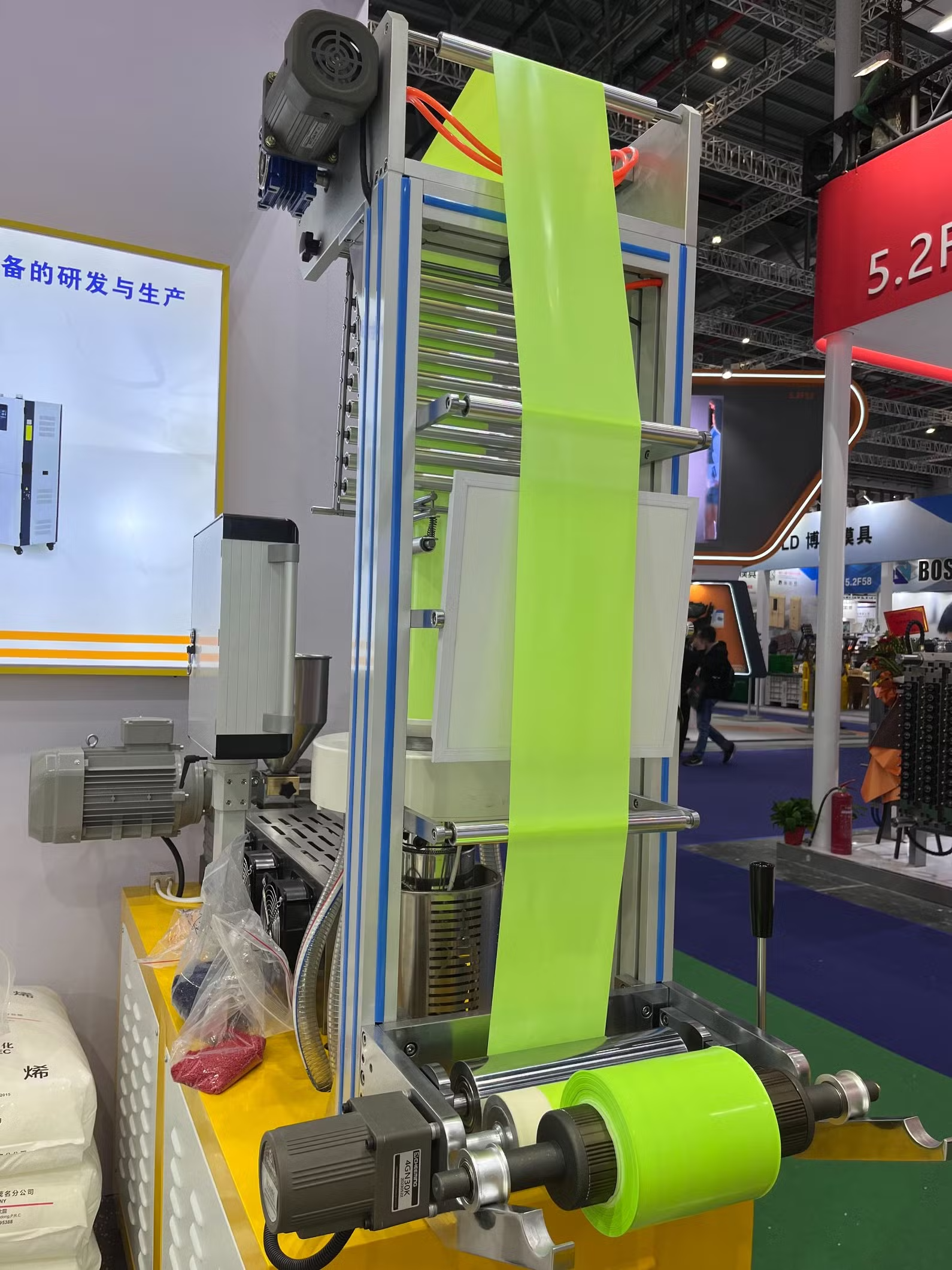

Film blowing machine blowing all kinds of color film:

Details images

Film blowing device Winder

Film blowing device Winder

Control panel Assembly process

Control panel Assembly process

These devices work together to enable the operation of the machine to test the feasibility of blowing film of the polymer material and the condition of the gum in the material, as well as the dispersion of colored dispersions, control mixtures, and extrudates.

Packing&Delivery

First, wrap the fuselage with a winding film to initially ensure the stability of the fuselage;Then wrap a circle again with pearl cotton, which has a certain thickness and is soft, and can prevent damage to the machine due to bumps during transportation;Finally, the machine is placed in a wooden box tailored to its size to ensure the safety and stability of the machine during transport.

First, wrap the fuselage with a winding film to initially ensure the stability of the fuselage;Then wrap a circle again with pearl cotton, which has a certain thickness and is soft, and can prevent damage to the machine due to bumps during transportation;Finally, the machine is placed in a wooden box tailored to its size to ensure the safety and stability of the machine during transport.

Certifications

Why Choose Us

1) Application: PE, modified PP, modified PET, and other plastic materials which could be blown.

2) New material formula development.

3) Film blowing property test.

4) Master batch color dispersion test.

5) Optimization of blown film production technology.

6) Production of simple layer tubular film blowing.

| SPECIFICATIONS FOR XH-430 LAB BLOWN FILM MACHINE | |

| Screw diameter | 25 mm |

| Screw L/D | 33:1 |

| Screw rotating speed | 0-95 rpm |

| Main motor power | 2.2KW |

| Film thickness | 0.02-0.2mm |

| Max film width | 180mm |

| Power supply | 380V/50Hz/3 phases or customerized |

| Control system | SIEMENS PLC touching screen control |

Main Features

1) Specially manufactured screw and barrel to guarantee precision and quality;

2) International brand variable speed control motor to precisely control the screw rotating speed;

3) The lab blown film machine frame can be electrically lifted, which is easy to lead the film and adjust the production technology;

4) Equipped with retractable unit for the blown film frame to easily transport and move;

5) SIEMENS touching screen PLC control system.

Details Images

Film blowing machine blowing all kinds of color film:

Details images

These devices work together to enable the operation of the machine to test the feasibility of blowing film of the polymer material and the condition of the gum in the material, as well as the dispersion of colored dispersions, control mixtures, and extrudates.

Packing&Delivery

First, wrap the fuselage with a winding film to initially ensure the stability of the fuselage;Then wrap a circle again with pearl cotton, which has a certain thickness and is soft, and can prevent damage to the machine due to bumps during transportation;Finally, the machine is placed in a wooden box tailored to its size to ensure the safety and stability of the machine during transport.

First, wrap the fuselage with a winding film to initially ensure the stability of the fuselage;Then wrap a circle again with pearl cotton, which has a certain thickness and is soft, and can prevent damage to the machine due to bumps during transportation;Finally, the machine is placed in a wooden box tailored to its size to ensure the safety and stability of the machine during transport.Certifications

Why Choose Us

Our Company :Guangdon g Xihua Machinery Co., Ltd. is a laboratory equipment high-tech enterprise that integrates research and development, manufacturing, sales, and service.

The company was founded in 1995 and is headquartered in Dongguan, Guangdong. The factory covers a total area of 15000 square meters. It has passed ISO quality management system certification and CE EU'safety certification.

The company was founded in 1995 and is headquartered in Dongguan, Guangdong. The factory covers a total area of 15000 square meters. It has passed ISO quality management system certification and CE EU'safety certification.

Our strength:The factory covers a total area of 15000 square meters. It has passed ISO quality management system certification and CE EU'safety certification. We have multiple sets of domestically advanced fully automatic production equipment, independent research and development laboratory, multifunctional exhibition halls, and advanced testing and analysis instruments.

Our commitment:

>>24-hour service

>>personalized customization

>>20+ years manufacture experience

>>lifetime after-sales service

>>6000+ cooperative customers

>>product quality assurance

>>24-hour service

>>personalized customization

>>20+ years manufacture experience

>>lifetime after-sales service

>>6000+ cooperative customers

>>product quality assurance