Customized Twin Screw Extruder for Masterbatch Compounding and Mixing

At Manor Engineering, we take advanced technologies — mainly from China, Europe, and the U.S. — and transform them into reliable, customized solutions for the Israeli market. Hardware arrives directly at our California R&D facility, where we redesign and prototype each product for optimal performance. From there, we move to scaled manufacturing, ensuring quality and consistency. By combining hardware, software, and multidisciplinary engineering, we deliver complete solutions — fully controlled by us and supported locally. No dependency on foreign service. No compromise on reliability.

$38000

- Shipping:

Learn More

Basic Info.

Model NO.

SM52

Plastic Processed

PA

Product Type

Granulating Extruder

Feeding Mode

Multiple Feed

Assembly Structure

Integral Type Extruder

Screw

Twin-Screw

Engagement System

Full Intermeshing

Screw Channel Structure

Deep Screw

Exhaust

Exhaust

Automation

Automatic

Computerized

Computerized

Output (Kg/H)

2500-3500kg/H

Weight

Around 13000kg

Certification

CE

Power (Kw)

315

Screw Speed (Rpm)

900 Rpm

Screw Diameter (mm)

52

Screw L/D Ratio

20-68

Transport Package

Container

Trademark

SUNMAC

Origin

China

HS Code

84772090

Production Capacity

1

Packaging & Delivery

Package Size

700.00cm * 200.00cm * 200.00cm

Package Gross Weight

400.000kg

Product Description

Product Parameters

| Model | Diameter (mm) | L/D | Screw speed (rpm) | Motor Power (KW) | Torque per shaft (N·m) | Specific torque T/A3 | Capacity (kg/hr) |

| SM26plus | 26.5 | 24~68 | 900 | 22 | 117 | 11.8 | 10~90 |

| SM36plus | 36.1 | 24~68 | 900 | 55 | 292 | 11.8 | 90~270 |

| SM42plus | 41.5 | 24~68 | 900 | 90 | 478 | 11.8 | 180~450 |

| SM52plus | 51.8 | 24~68 | 900 | 185 | 982 | 11.8 | 360~900 |

| SM63plus | 62.6 | 24~68 | 900 | 315 | 1671 | 11.8 | 600~1700 |

| SM73plus | 72.2 | 24~68 | 900 | 500 | 2653 | 11.8 | 2000~5000 |

| SM96plus | 93.8 | 24~68 | 900 | 1000 | 5306 | 11.8 | 3400~8500 |

| SM135plus | 132 | 24~68 | 900 | 1700 | 9019 | 11.8 | 3400~8500 |

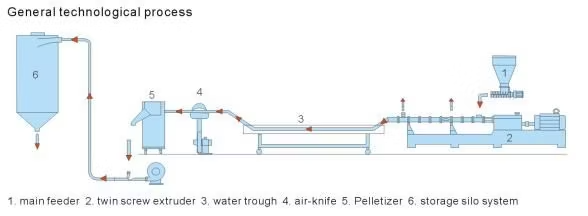

Applications

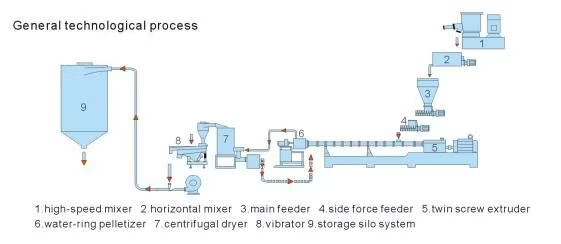

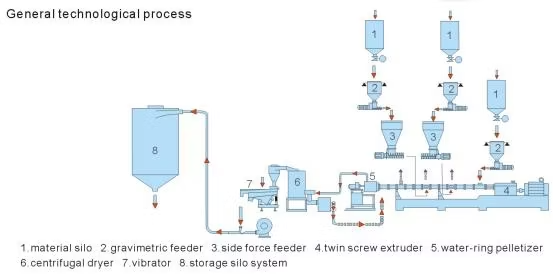

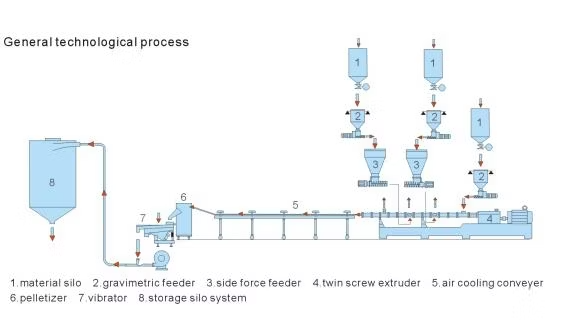

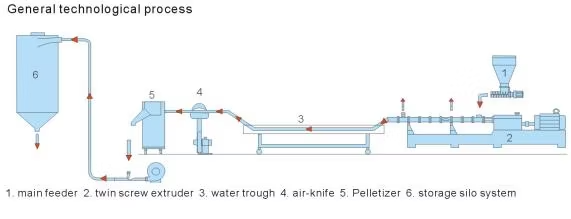

Based on new design, output can reach more than 3 tons per hour, air cooling, water ring or under water system is optional.

Typical formulation

PE, PP, EVA, etc. + Calcium carbonate, talc powder, titanium powder;

ABS, PC; PS, etc. + aluminum hydroxide, magnesium hydroxide, antimony oxide;

PP, PA, ABS+ ferrous powder, sulphuric powder, ceramic powder.

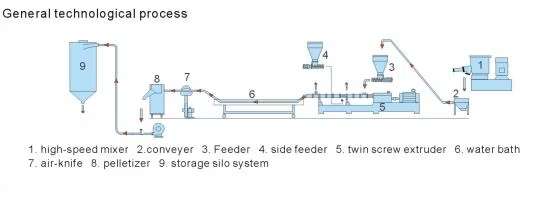

2.High performance filler masterbatch and modification

2.High performance filler masterbatch and modificationAdopting the multi-feeding method with high speed side force feeder, suitable for high-class filer masterbatch with low additive formula.

Typical formulation

PE, PP, etc. + calcium carbonate, talc powder + less additives

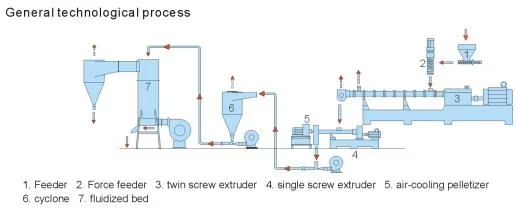

3.Application advantage of biodegradable masterbatch

3.Application advantage of biodegradable masterbatchAdapted to the physical characteristics of degradable material, air cooling or water cooling pelletizing system is available.

Typical formulation

PLA, PBAT etc. + CaCO3 powder, talc powder, etc.

4.Advantages in additives masterbatch

4.Advantages in additives masterbatchPrecisely control the material flow state in the machine, anti-block masterbatch, slip masterbatch, antistatic masterbatch, etc.

Typical formulation

PP, PA, ABS, PBT, etc. + anti-burning agent and other additives; anti-flaming masterbatch;

PE, PP, PS, etc. + starch; degradable masterbatch

PE + fog-preventing dipper, stabilizer, UV masterbatch

PET, PP, PE, anti-block masterbatch, slip masterbatch, antistatic masterbatch.

5.Advantages in color masterbatch

5.Advantages in color masterbatchBased on new solution, obviously improve dispersion.

Typical formulation

PE, PP, ABS, AS, PA, EVA, PET + pigment and auxiliary

6.Advantages in plastic alloy and engineering plastics modification

6.Advantages in plastic alloy and engineering plastics modificationSuitable for a variety of formula, accurate ratio, excellent mixing effect.

Stable performance, adapt to the high quality, high capacity production requirements.

Typical formulation

PE, PP, PS + SBS; PA + EPDM; PP + NBR; EVA + Silicon rubber, etc.:

PE, PA, PC, CPE + ABS (alloy); ABS + TPU; PBT + PET; PP+PE, etc.

chopped glass fibres, carbon fibres, crystals and so on, etc.

EVA heat-melting glue, polyurethane, fluorin rubber, fluorine plastics, PP cigarette filtering material and TPR sole material.

7.Advantages in cable material

7.Advantages in cable materialAdapt to a variety of formulations, stable product quality, high capacity, low energy consumption.

Typical formulation

HDPE, LDPE, LLDPE, MDPE, EVA, PVC, PP, etc. Insulating cables, coatings; PE peroxide, silicon cross-linking cables; radialization cross-linking cables.

Company Profile

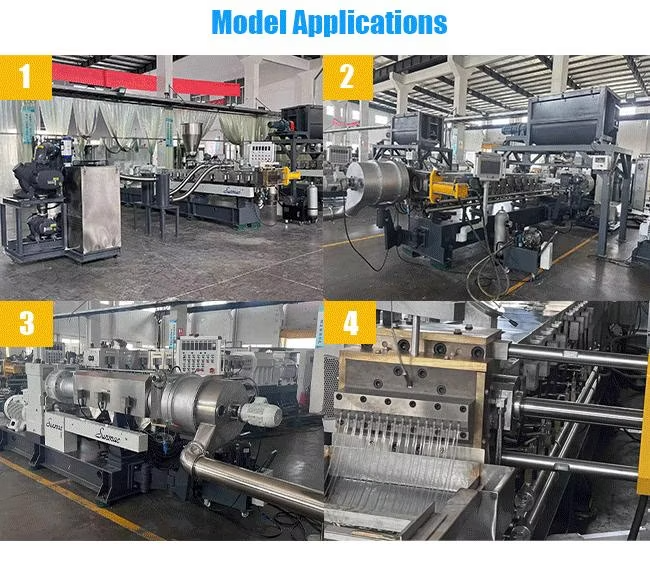

Model Applications

Certifications

Packaging & Shipping

Exhibitions