Robot Palletizing Machine Automatic Feed Palletizer Palletizer Material Handling Manipulator Machine

At Manor Engineering, we take advanced technologies — mainly from China, Europe, and the U.S. — and transform them into reliable, customized solutions for the Israeli market. Hardware arrives directly at our California R&D facility, where we redesign and prototype each product for optimal performance. From there, we move to scaled manufacturing, ensuring quality and consistency. By combining hardware, software, and multidisciplinary engineering, we deliver complete solutions — fully controlled by us and supported locally. No dependency on foreign service. No compromise on reliability.

Learn More

Basic Info.

Product Description

• Reduce labor costs: reduce dependence on labor and reduce labor costs;

• Improve the working environment: the system can work in high temperature, high humidity, high dust and other harsh environment, reducing the labor intensity of workers;

• Improve safety: The system can replace manual hazardous work such as high altitude and heavy objects to reduce safety risks in the workplace;

• Improve production efficiency: The system can work consistently and efficiently, greatly improving production efficiency;

• Error reduction: Precise control through 3D visual recognition and deep learning enables robots to reduce human errors and improve product quality;

• Strong flexibility: according to different goods and working environment, fast and accurate handling route and action planning, flexible intelligent production.

The main configuration | 304 stainless steel finger diameter Phi =18mm, finger spacing, center line and roller spacing to keep the same. | |||

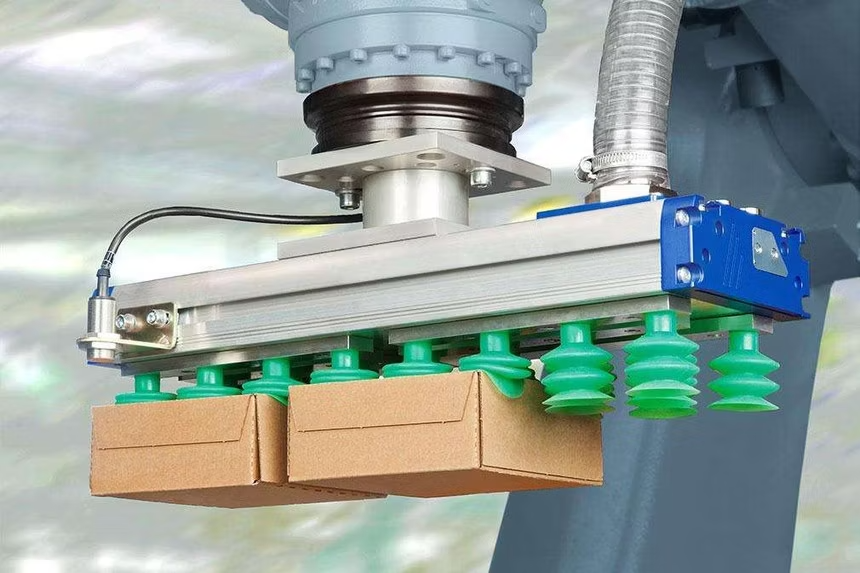

Brand configuration | SMC pneumatic components | |||

Drive mode | pneumatic drive, with pressing device | |||

Connection with the robot | flange connection | |||

Grasp structure | frame adopts high strength aluminum alloy, adjustable width | |||

Basic data | maximum load 180Kg; Repeated positioning accuracy ±0.4mm; Protection class IP65; Demonstrator T70 | |||

Maximum working radius | 3200mm | |||

Total weight of robot body | 1400Kg | |||

Maximum speed | J1 axis 114°/sec J2 axis 108°/sec J3 axis 119°/sec J4 axis 290°/sec | |||

Founded in 2012,sanad is a national high-tech enterprise,with machine vision technology as the core,through deep learning algorithm,image processing algorithm,pattern recognition algorithm,video analysis algorithm,arm/FPGA/DSP embedded software and hardware development .industrial visual positioning .visual tracking,visual detection,multi-sensor information fusion and other technical means,in the field of smart logistics,we have found a suitable application scenario of machine vision to realize "machine generation"reduce costs and increase efficiency for enterprises ,and empower the smart logistics industry.

Continue R&D and innovation in the fields of smart factory and smart storage,so that the logistics industry and manufacturing industry all over the world can enjoy the achievements of Chinese science and technology!

High-tech with research anddesign capacity

Concentrated on DWS equipment and sorting warehousing system overall solution

Related software and system are with patents

Stable and mature supplying system

Young active sales and engineers for instant services(16-20 hours online)