Super-Thin Film Industry Packaging LLDPE Shrink Film Extruder Machine

At Manor Engineering, we empower new factories with the right technology to rise fast. Introducing our Single-Screw HDPE / LDPE Film Blowing Machine — a dual-purpose, thin-film powerhouse designed for startups and smart investors. ✅ Two materials, one machine: Swap the die head and instantly switch between HDPE and LDPE film — giving you flexibility without extra cost. ✅ Built to last: The extruder, screw, and cylinder are precision-machined from high-grade nitrided alloy steel — for high hardness, minimum wear, and strong corrosion resistance. ✅ Superior plasticizing: Our custom screw design ensures excellent melt quality, enabling thin-film blowing with high clarity and strength. ✅ Energy-smart by design: A frequency-controlled main motor delivers rock-solid speed stability — while saving up to 30% in electricity every shift. ✅ Start small. Think big. Capable of blowing films from LDPE, HDPE, and LLDPE, it’s perfect for producing: Food packaging Garment & textile bags Garbage and vest-style carry bags Whether you’re producing small rolls or wide films, the enhanced 38CrMoAl nitrided screw barrel delivers high cooling efficiency and stable output across the board. Ideal for entrepreneurs building their first production line… and engineered to scale with your ideas. From hardware to AI — with seven partner factories under NDA across China, USA, and Europe — Manor Engineering isn’t just delivering machines. We’re building your future, one smart solution at a time. Manor Engineering — Start Strong. Scale Fast. Think Smart.

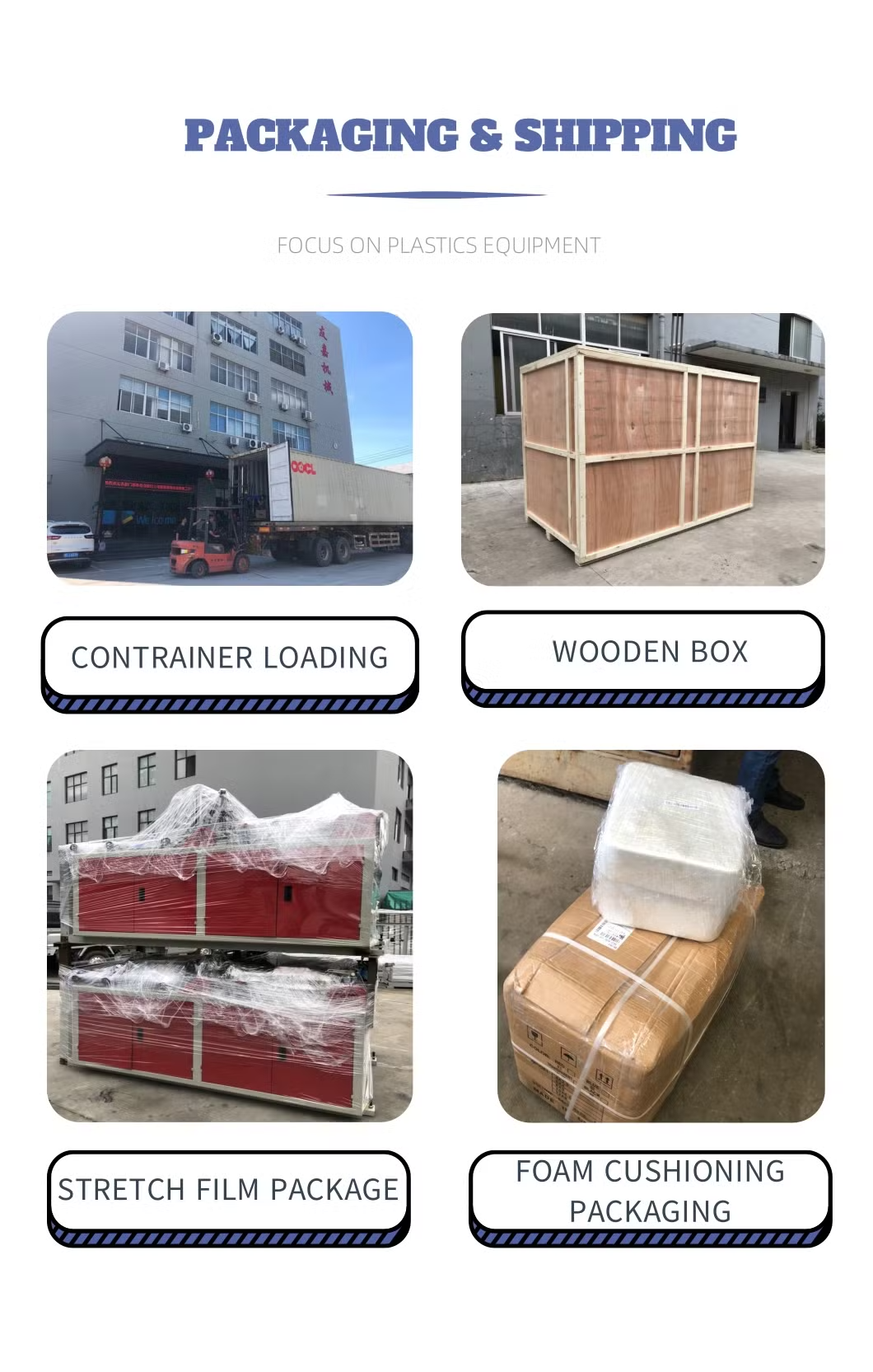

- Shipping:

Learn More

Basic Info.

Packaging & Delivery

Product Description

Product Description

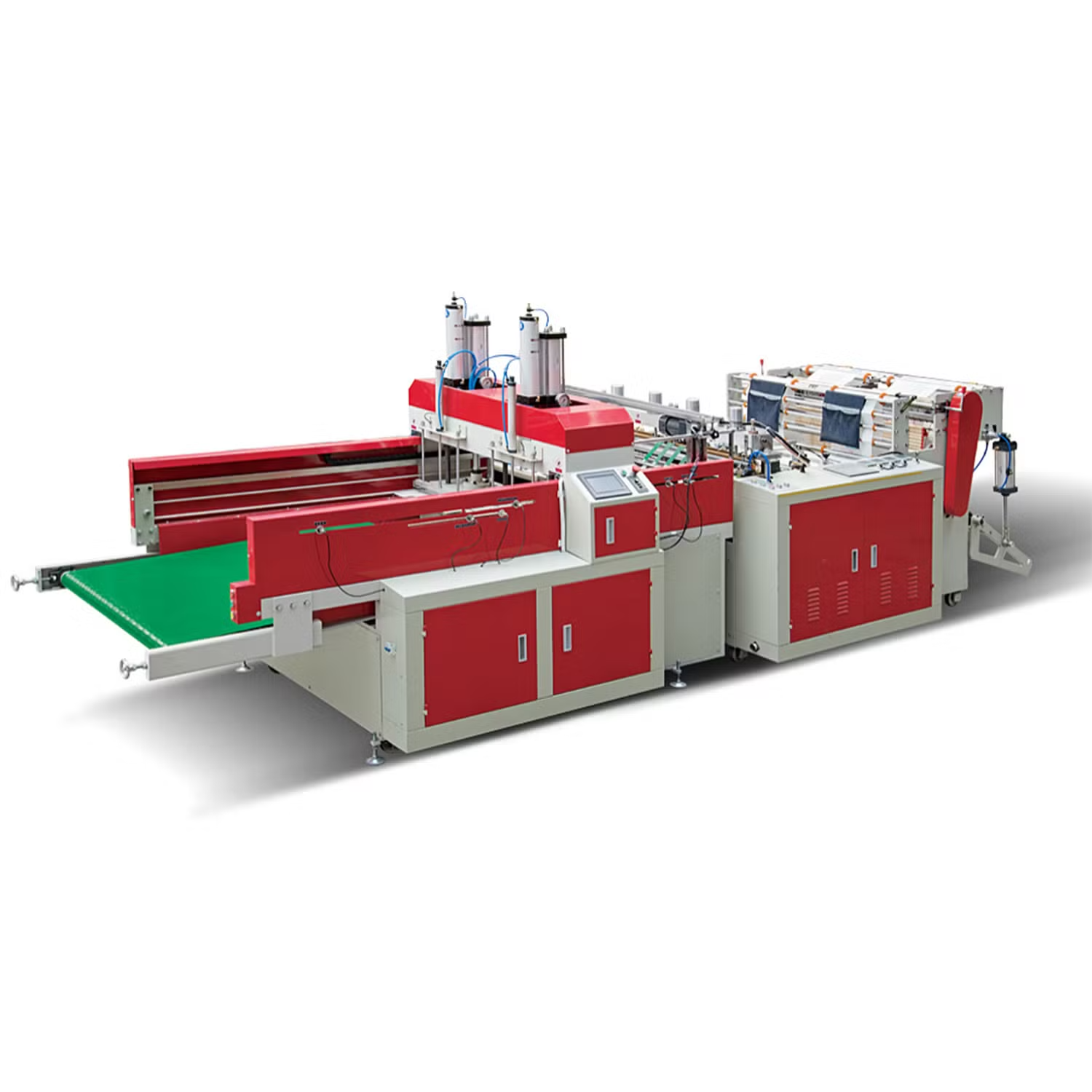

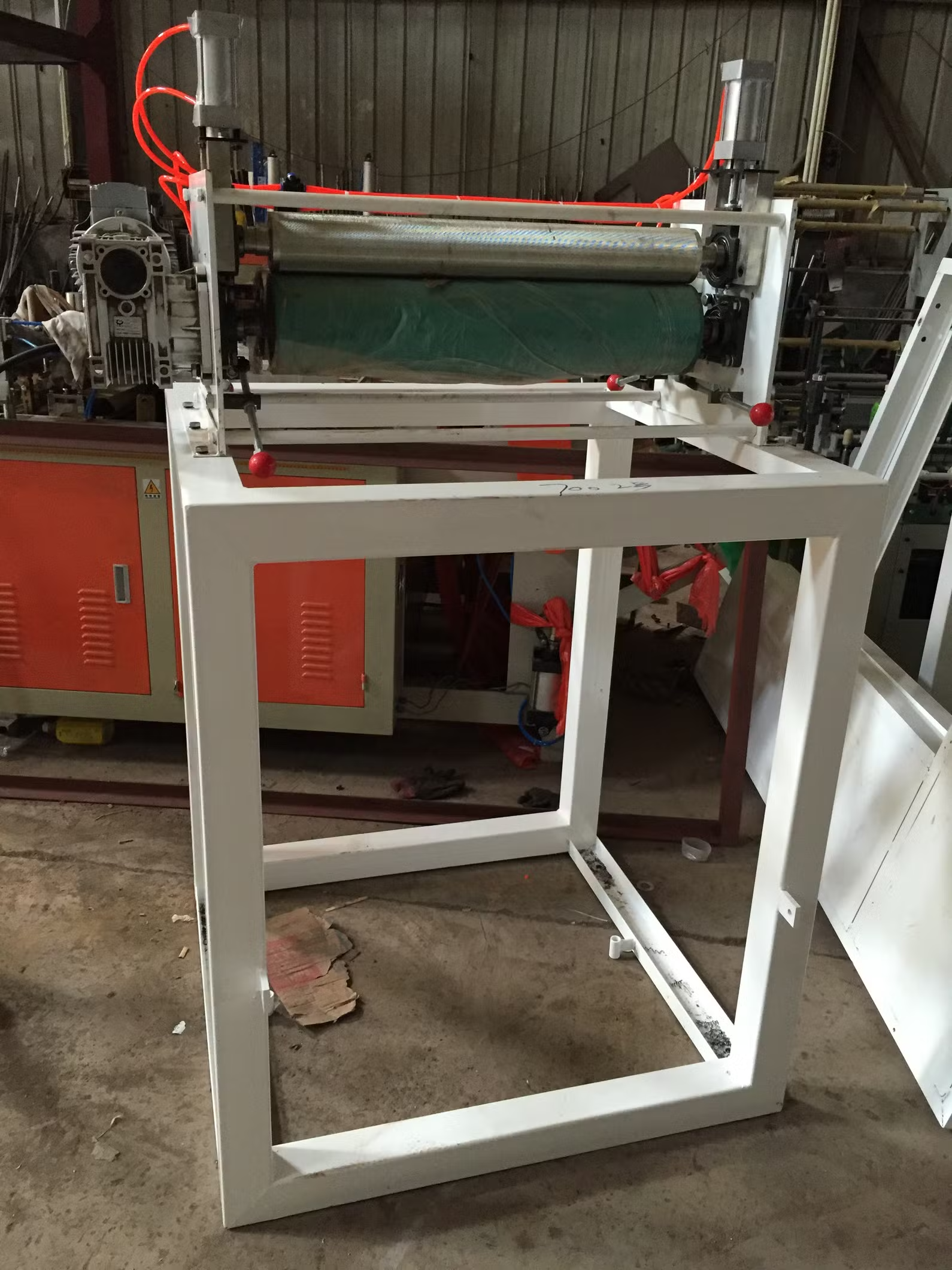

Single Screw HDPE/LDPE Film Blowing Machine

This machine is very suitable for producing very thin film.A cost-effective and affordable machine is undoubtedly the best choice for you to start a new business. This machine can produce films of two different materials by simply replacing the film head,HDPE film and LDPE film,making it a dual-purpose machine.

Its extruder, cylinder and screw rods are made of quality alloy steel that have been nitrized and processed in a precision way. Hence it is sound in hardness, durable in corrosion resistance. The specially-designed screw is of sound quality in plasticizing, which helps increase the production capacity.It is applied to blowing the plastic films like low density polygene (LDPE), high density polytene(HDPE) and linear low density polytene (LLDPE). It is widely applied to producing the packing bags for foodstuff, clothing, rubbish bag and vest ones.

The main motor adopts frequency conversion speed control, which increases the stability of the main machine speed control, and can save electricity by 30%. The screw barrel is made of 38 chrome molybdenum aluminium, which is treated by nitriding, and the cooling effect can reach the best regardless of blowing large or small size films;

This Single layer blowing machine unit is suitable for customers who have just set up factories and have limited budgets. If you need a higher output machine or a higher quality machine, you can consult our company in detail.

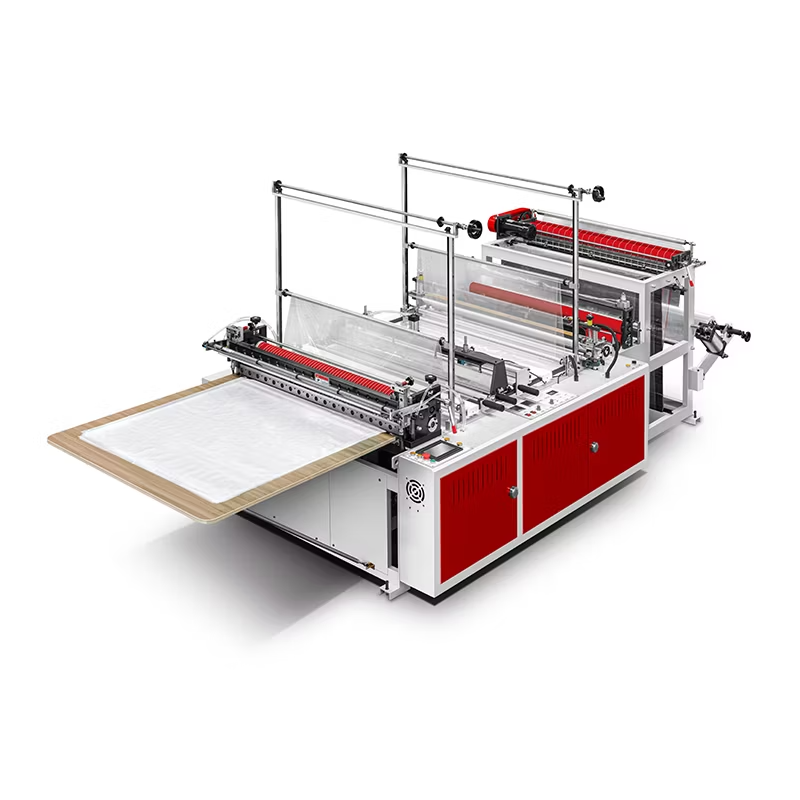

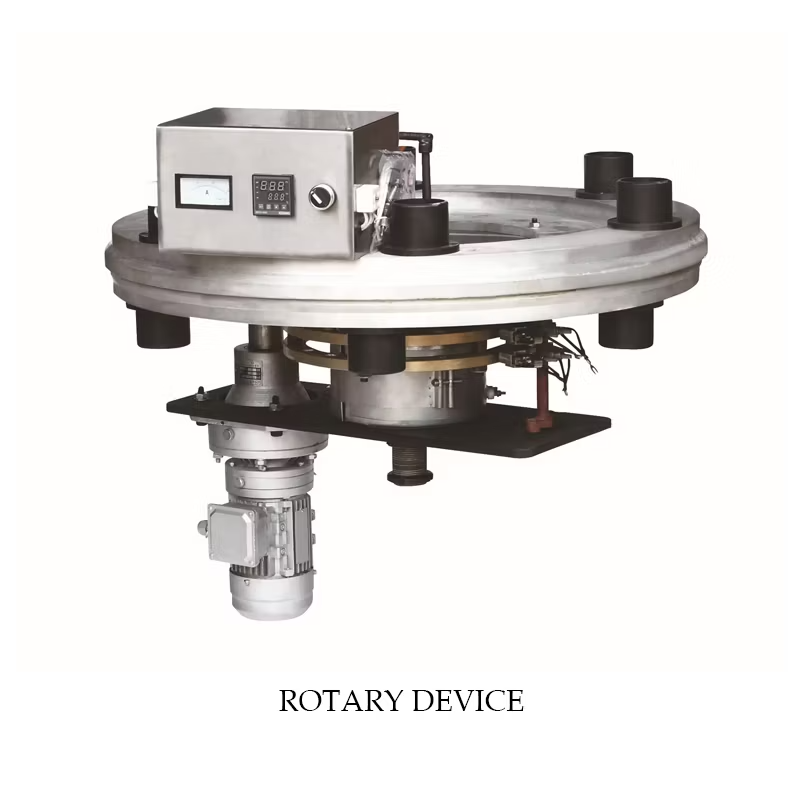

Optional Equipment

Product Parameters

| Model | XY-A50 | XY-A55 | XY-A60 | XY-A65 |

| Raw material | HDPE, LDPE, LLDPE | |||

| Screw diameter | φ50 | φ55 | φ60 | φ65 |

| Screw L/D radio | 28:1 | 28:1 | 28:1 | 28:1 |

| Max. folding width of film | 600mm | 800mm | 1000mm | 1200mm |

| Single-sided thickness of film | 0.01-0.10mm | 0.01-0.10mm | 0.01-0.10mm | 0.01-0.10mm |

| Main motor | 11kw | 15kw | 18.5kw | 18.5kw |

| Max output | 35kg/h | 55kg/h | 65kg/h | 80kg/h |

| Total power | 20kw | 25kw | 30kw | 40kw |

| Weight | 1.5T | 2T | 2.3T | 2.6T |

| Outline diameter | 5*2.2*4.2m | 5*2.4**4.8m | 6.5*2.3*4.9m | 6.5*2.5*5.6m |

Recommend Machine

Detailed Photos

Packaging & Shipping